FS-20

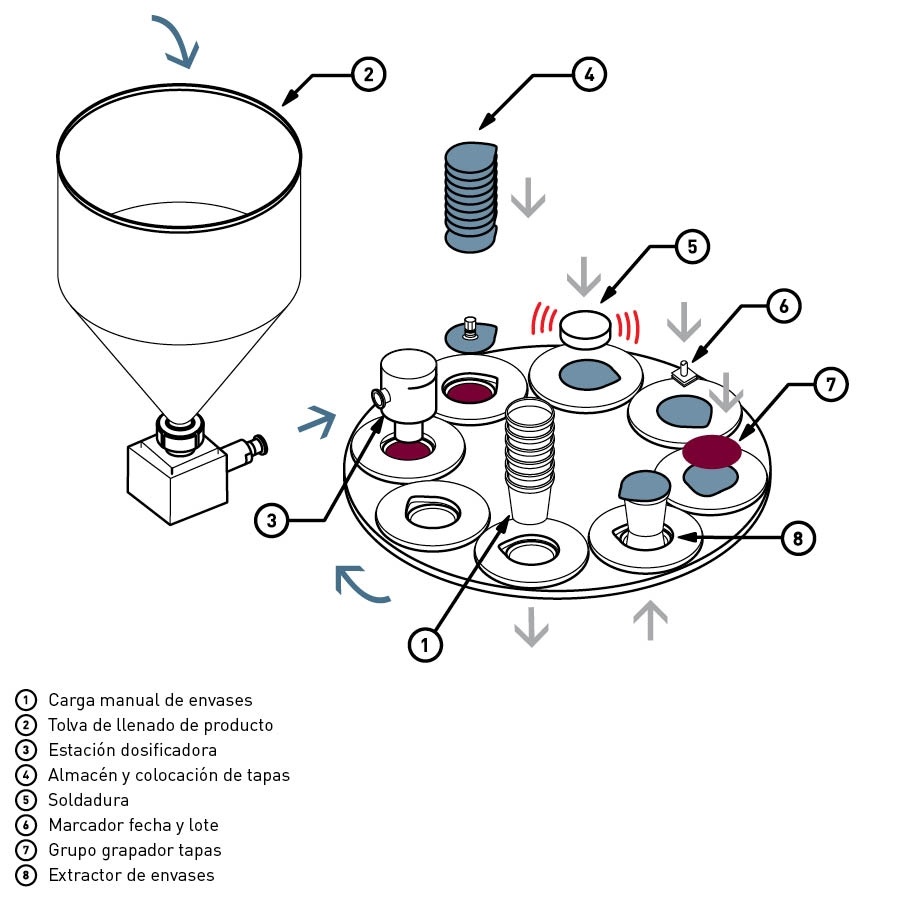

AUTOMATIC MACHINE FOR FILLING AND CLOSING RIGID, UPSTACKING CONTAINERS, BY MEANS OF HEAT SEAL TECHNIQUE, STARTING OUT FROM PRE-CUT LID.

EQUIPMENT

· Intermittent rotary unit with 8 stations for container transportation.

· Manual positioning of the container inside the rotary table.

· Filling head for liquid, viscous, solid or powder products.

· Hopper for product feeding.

· Anti-dripping nozzle.

· Destacking system for pre-cut aluminium lids.

· Heat seal system for container and lid, manually pulled down.

· Embossed system for adapting the lid to the container.

· Manual pulling out system of the container from the rotary unit.

OPTIONAL EQUIPMENT

· Filling head for liquid or viscous products, for filling products with two different flavours in the same container.

· Marker ink pad for expiration and batch.

· Positioning system for reclosable overcap.

· Automatic system for feeding the hopper.

· Automatic C.I.P. cleaning system.

· Format kit for conditioning of different containers with rapid format change (10 minutes).

· Laminar flow cabinet.

TECHNICAL FEATURES

Height 1.800 mm

Width 1.050 mm

Length 950 mm

Weight 420 Kg

Power supply Three-phase 380V + neutral

Peumatic supply 6 bar

Capacity Up to 1.000 containers

Download our catalogue